Bridging the gap between innovation and execution: Integrating PDRI and TRL for smarter mining projects

- Post Date

- 10 July 2025

- Read Time

- 6 minutes

Mining of critical metals is expected to see significant growth demand, due to geopolitical factors, trade tariffs, protectionism, and a renewed interest in domestic and downstream metals processing. However, project execution in metals and mining has historically been poor and mining projects have systematically underperformed.[1] According to a recent McKinsey article, cost and scheduling challenges have affected more than 80% of recent major mining and metals projects.[2]

In the high-stakes world of mining, where capital intensity meets geological uncertainty, project success hinges on two critical factors: clarity of scope and maturity of technology. Yet, these are often treated in isolation. What if we could integrate two powerful methodologies: Project Definition Rating Index (PDRI) and Technology Readiness Level (TRL), to create a unified framework for de-risking mining investments?

The case for integration

PDRI, developed by the Construction Industry Institute (CII), is a powerful and structured tool that assesses the completeness of project scope definition. It helps project teams identify gaps early, prioritize planning efforts, and improve predictability in cost, schedule, and performance.

The PDRI is intended for use during front end planning (FEP), the project phase that encompasses activities such as feasibility, concept, and detailed scope definition (see Figure 1). The first task is to identify the key standard deliverables in each of the project’s design work stages to confirm the maturity of the scope.

Source: CII

How PDRI scoring works

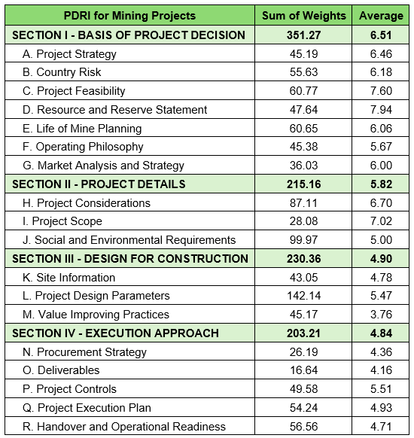

PDRI – FR-366, Specific for Mining Projects consists of a standardized, comprehensive checklist of 180 scope definition elements in an easy-to-use score sheet format that is divided into four sections and 18 categories. Table 1 shows the total and average weights allocated to each section and category.

Source: CII

Each element is assigned a weight based on its impact on project success. During assessment, team members score each element from 0 to 5, where: 1 = well defined, 5 = poorly defined or missing. The scores are multiplied by their respective weights and summed to produce a total PDRI score, typically ranging from 0 to 1000.

Interpreting the PDRI score

- 0 – 100: Excellent definition – low risk

- 101 – 200: Good definition – moderate risk

- 201 - 300: Fair definition – elevated risk

- 301 – 1000: Poor definition – high risk

Lower scores indicate better scope clarity and readiness for execution. A PDRI score of 200 or less has been shown to greatly increase the probability of a successful project. The PDRI score can be tracked over time to monitor planning progress and used as a gate criterion for project phase approvals.

How TRL scoring works

TRL, originally developed by NASA and widely adopted across industries, evaluates the maturity of technology from concept (TRL 1) to full deployment (TRL 9). The TRL Assessment Tool groups nine technology readiness levels into four technology development stages:

- Fundamental Research

- Research and Development

- Pilot and Demonstration

- Early Adoption

The tool provides a description of each TRL along with a checklist to determine if the technology is at that specific TRL. For a detailed breakdown of TRL definitions and checklists, refer to the Government of Canada TRL Assessment Tool. [3] If there are uncertainties as to whether a technology is at a certain TRL, then the lower TRL should be assigned. An important principle in guiding TRL determination is to be clear in understanding how the testing environment represents real-world conditions in deployment. It is particularly useful in mining, where emerging technologies, such as ore sorting, autonomous haulage, or novel processing methods can make or break a project.

When used together, PDRI and TRL offer a dual-lens view: one focused on project scope and the other on technology maturity. This integration is especially valuable in mining, where innovation is increasingly central to competitiveness, sustainability, and safety.

Why mining projects need PDRI and TRL

Mining projects are uniquely complex:

- Long lead times and high capital costs demand rigorous front-end planning.

- Technological innovation is often essential to access lower-grade ores or meet ESG targets.

- Regulatory and stakeholder pressures require transparency and risk mitigation.

By combining PDRI and TRL, mining companies can:

- Align technology decisions with project readiness: Avoid deploying immature technologies in projects that are otherwise execution ready.

- Prioritize planning based on technology maturity: Use TRL insights to inform which areas of the project need deeper definition or contingency planning.

- Improve investment confidence: Provide boards and investors with a clearer picture of both scope clarity and innovation risk.

A practical framework

Here’s how mining companies can undertake this integration:

- Map TRL assessments to PDRI elements: For example, if a novel ore processing method is at TRL 5, the PDRI elements related to process design, equipment selection, and commissioning should be flagged for deeper planning.

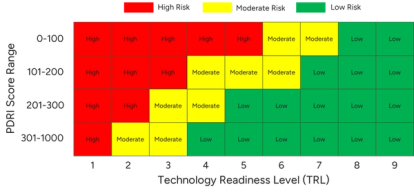

- Use a readiness matrix: Plot PDRI scores against TRL levels to visualize project risk zones, e.g., high PDRI score + low TRL = high innovation risk (see Figure 2).

- TRL 1–9: Represents the maturity of the technology, from concept (1) to fully operational (9).

- PDRI Score Ranges: Indicates the level of project scope definition. Lower scores mean better-defined projects.

- Colour Coding:

- Green (Low Risk): High TRL and well-defined scope.

- Yellow (Moderate Risk): Either scope or technology maturity needs attention.

- Red (High Risk): Immature technology and poorly defined scope - high potential for project failure.

- Stage-gate alignment: Ensure that both PDRI and TRL thresholds are met before advancing to the next project phase (e.g., from Pre-feasibility to Feasibility).

Conclusion: Smarter decisions, better outcomes

In an era where mining must be more agile, sustainable, and capital-efficient, integrating PDRI and TRL is not just a best practice, it is a strategic imperative. The use of dual readiness indicators (PDRI and TRL) can help to improve investment confidence. By bridging the gap between what we know (scope) and what we can do (technology), mining leaders can make smarter decisions, reduce surprises, and deliver projects that are both innovative and executable.

How SLR can help

SLR has a dedicated mining advisory team of over 230 professionals globally, providing leading scientific and engineering solutions for mining projects. Among the 230 professionals, there are subject matter experts in all technical areas, e.g., Geology, Mining, Metallurgy and Processing, Tailings, Geoscience, etc. We have expertise in applying PDRI and TRL methodologies and can assist clients in the mining sector align technology decisions with project readiness and prioritize planning based on technology maturity.

Contact us to discuss furtherReferences:

[1]Mulder, H. and Bekker, M.C. 2022. A review of readiness assessments for mining projects. Journal of the Southern African Institute of Mining and Metallurgy, Vol. 122, No. 7, pp. 377-386.

[2] McKinsey & Company. 2024. The capex crystal ball: Beating the odds in mining project delivery. November 2024.

[3] Government of Canada. 2025. https://ised-isde.canada.ca/site/clean-growth-hub/en/technology-readiness-level-trl-assessment-tool. Accessed: June 5, 2025.

Recent posts

-

-

Unlocking value through solar PV repowering: A focus on module replacement and DC/AC optimisation

by David Fernandez

View post -